X390 LAWN TRACTOR 48 IN

Lawn Tractor with 48-inch Deck

- 48-in. Accel Deep™ Deck

- Easy mulching with optional MulchControl™ Kit (one-touch or from deck versions)

- Powered by 22 hp (16.4 kW)* iTorque™ Power System

- Automotive-style power steering

- 4 year/300 hour bumper-to-bumper warranty

View Product Brochure

Features

22-hp (16.4-kW) V-twin engine

22-hp (16.4-kW) V-twin engineThe tractor is powered by a John Deere iTorque™ power system, a combination of engine features and an exclusive hood design that provide superior lugging ability, even cooling, and durability.

A 22-hp (16.4-kW) V-twin engine provides plenty of power and torque to handle tough mulching, mowing, and bagging conditions.

Key engine features include:

- 22 hp (16.4 kW)

- Large 726-cc displacement

- V-twin air-cooled design that provides smooth, quiet power

- Quality features include:

- Cast-iron cylinder liners

- Overhead valves

- Full-pressure lubrication

- Replaceable oil filter

- Dual-stage air cleaner V-twin design:

- Excellent power and performance

- Easy starts

- Smooth operation

Flywheel alternator

A flywheel alternator provides plenty of capacity to quickly recharge the battery and power electrical equipment, such as lights or a sprayer:

- 15-amp capacity

- Regulated to keep the battery at full charge without risk of overcharging

Fuel tank has large, 3.3-U.S. gal. (12.5-L) capacity

Fuel tank

Fuel tank Electronic fuel gauge

Electronic fuel gaugeLarge fuel tank and convenient fuel gauge minimize the number of stops for fuel and chance of running out of fuel:

- Fuel tank has a large, 3.3-U.S. gal. (12.5-L) capacity for more hours of operation between refills.

- Large, 3-in. (7.6-cm) diameter fuel tank filler opening makes adding fuel easy.

- Located on the left fender

- Helps eliminate spillage

- Electronic fuel gauge on the dash display allows the operator to easily monitor the amount of fuel in the tank.

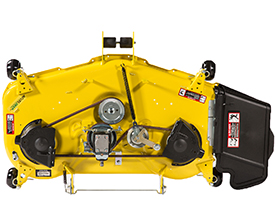

X394 with Accel Deep 48A Mower

X394 with Accel Deep 48A Mower Accel Deep 48A Mower

Accel Deep 48A MowerThe 48-in. (122-cm) Accel Deep Deck uses the latest in three-spindle mowing technology to raise performance to a higher level:

- 10-gauge, 0.135-in. (3.4-mm) deck stamping for long life

- Deep, flat-top deck design to handle a large volume of material at faster mowing speeds

- Gives excellent cut quality and uniform discharge

- Easy to keep clean on top of and under the deck

- Resilient four-point mounting system suspends mower from tractor for a smooth and level cut

- Wide mower wheels easily adjusted just above ground level to help prevent scalping

- 0.25-in. (6.4-mm) cut-height increments allow mower to be set at the desired cut height

- Onboard deck-leveling system makes keeping mower properly adjusted easy

- Compatible with optional MulchControl™ mulching system

- Compatible with high-performance Power Flow™ material collection systems

- For use on X330, X350, X354, X370, X380, X384, X390, X394, X570, X580, X584, and model year 2016 X590 Tractors

The 48-in. (122-cm) Accel Deep Mower Deck is a stamped-steel, deep, flat-top design that delivers excellent cut quality, productivity, cleanliness, durability, and versatility. Optimal performance and dispersion of clippings is provided, even at faster mowing speeds:

- 4.83-in. (12.3-cm) depth throughout the entire deck shell for optimum mowing, mulching, and bagging performance

- Optional lever-action or electric one-touch MulchControl attachment provides superior mulching performance and versatility.

- Stamped-steel design eliminates sharp edges and corners where material can build up and diminish mowing performance

- Mower deck is suspended from the vehicle for a smooth and level cut

- Adjustable mower wheels, positioned just above ground level, help reduce scalping

Excellent cut quality

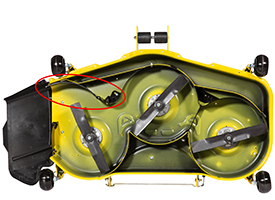

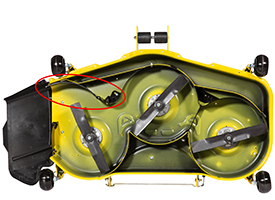

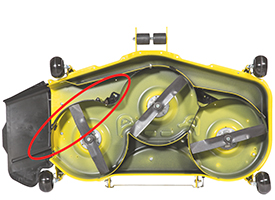

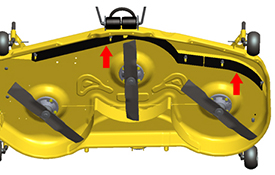

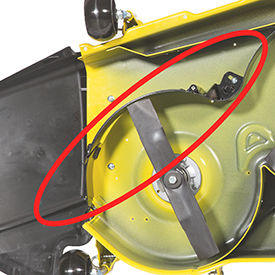

48A Mower top (similar mower from X700 Series Tractor shown)

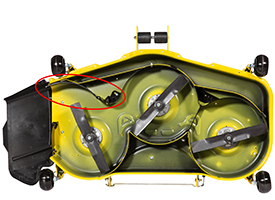

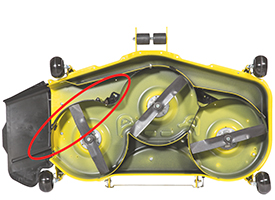

48A Mower top (similar mower from X700 Series Tractor shown) 48A Mower underside (similar mower from X700 Series Tractor shown)

48A Mower underside (similar mower from X700 Series Tractor shown)Deep mower-deck stamping gives excellent cut quality. It allows the cut and suspended material room to exit the deck without getting recut:

- Reducing the amount of re-cutting enables more power to be used to cut incoming grass, which greatly improves mower capacity.

- Helps maintain excellent cut quality at faster mowing speeds

- Clean flow of material out of discharge area prevents cut material from interfering with cutting the incoming grass, making it possible for the blades to cut incoming material cleanly.

- Even in mulching mode, cut evenness is improved compared to other designs because the additional depth allows for continuous circulation, optimal re-cutting, and an even distribution of clippings.

Productivity - getting the job done fast

Right side of Accel Deep 48A Mower Deck

Right side of Accel Deep 48A Mower DeckDeep mower-deck stamping gives high productivity, which gets the job done fast. It allows the cut and suspended material room to exit the deck quickly, reducing the amount of re-cutting so more power is available to process incoming grass:

- Greatly improves mowers capacity to maintain excellent mowing performance in difficult mowing conditions and at higher speeds

Large discharge opening is both high and wide to handle more material:

- Gives a smooth, even discharge of clippings at all mowing speeds

- Reduces the chance of plugging, especially important when operating in wet, thick, or dense grass and when bagging

- The 48A Power Flow blower has an inlet housing with over 50 percent greater area than the 48X Power Flow blower used on previous machines.

Cleanliness - for the mower and the operator

Accel Deep 48A Mower Deck

Accel Deep 48A Mower Deck Accel Deep 48A Mower Deck

Accel Deep 48A Mower DeckThe flat-top shape of the deck stamping is optimal for keeping itself and the operator clean:

- There are few places to catch and hold material on top and underneath the deck.

- Top of deck stays cleaner, reducing time and effort needed for cleaning and service

- Underside of deck is self-cleaning to maintain optimum performance without buildup of material to interfere with the flow of air and clippings

- Less need to clean and remove buildup of material from underside deck

- The depth of the Accel Deep mower deck minimizes the amount of material that escapes from the front of the deck:

- Limited amount of material to drift onto the operator and mower deck

- Even for material discharged out the chute, less re-cutting results in larger pieces that are less likely to end up on the operator

- Mulching prevents the discharge of material completely and the MulchControl attachment makes mulching a practical solution for most mowing situations.

Cleaning a mower deck, both top and bottom, is one of the most frequent maintenance activities:

- The flat-top design reduces places for material to build up and makes material that does collect easy to remove.

Mower wash port

Mower wash port Mower wash port with hose connector

Mower wash port with hose connectorA wash port is provided to make cleaning the underside of the mower deck easy.

- Hose connector is included with the mower deck.

Superior durability is designed in

Spindle pocket with flip-up cover

Spindle pocket with flip-up cover Easy-to-adjust mower wheel and mower side reinforcement

Easy-to-adjust mower wheel and mower side reinforcementThe 48A Mower Deck has strong spindle pockets, to keep the blades aligned, even after years of tough service:

- Ribs in the deck shell add strength where it is needed.

- The 48A has a 23 percent heavier overall weight than the Edge™ Xtra 48-in. (122-cm) mower deck used on previous machines.

Mower wheels are heavy duty:

- Provides greater strength and durability for longer, trouble-free life.

- Setting wheels to the correct height for the cutting height quick and easy.

Low-tension belt-drive design reduces the side load on engine lower bearings and mower deck bearings for longer life.

The 48A Mower Deck features a 5/8-in. (16-mm) diameter solid-steel rod side bumper that provides extra strength and protection.

Dual-stage E-coat and powder-paint coatings provide extra protection from rust.

Versatility - easy to change between side discharge, mulch, and bagging modes

The 48A Mower is designed for maximum versatility, providing the greatest ease in changing from one mower discharge mode to another:

- With an optional MulchControl attachment installed (along with the special mulching blades), changing from side-discharging to mulching or vice versa is done with the simple flip of a lever or push of an electric switch.

- The Power Flow rear bagger can be used with the MulchControl attachment and blades installed by simply using the MulchControl lever or electric one-touch switch to move the mulch baffle to the side-discharge position.

MulchControl option

A lever-action or electric one-touch MulchControl attachment for the 48A Mower Deck makes mulching more practical for many mowing situations because it not only does an excellent job of mulching but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect the lawn material. Advantages of mulching grass clippings include:

- A beautiful looking lawn

- Grass clippings not blown onto the operator, driveways, or flower beds

- Less fertilizer use

- Elimination of the effort needed to dispose of clippings

How MulchControl works

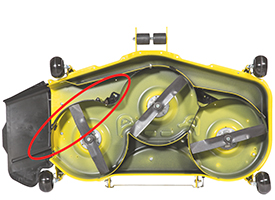

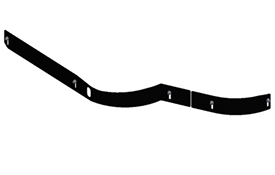

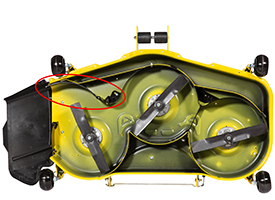

MulchControl baffle open

MulchControl baffle open MulchControl baffle closed

MulchControl baffle closedMulchControl is an innovative, simple design that is easy to use and maintain:

- The MulchControl attachment includes baffles to control the flow of material under the deck.

- The MulchControl baffle, or divider, between the left and middle spindles is about half way down. The height is designed to balance the mulching and side-discharge modes.

- When the MulchControl baffle is open, the divider between the left and middle spindles passes a portion of the material to the discharge opening, along with the material from the middle and right spindle areas.

- When the MulchControl baffle is closed, the material stays within the deck and gets chopped into mulch and deposited in the turf.

MulchControl handle

MulchControl handle Electric one-touch MulchControl switch

Electric one-touch MulchControl switch- For the lever-action MulchControl attachment, a handle on top of the mower deck is used to engage or disengage mulch mode.

- The operator is required to get off of the tractor in order to engage or disengage mulch mode with the lever-action system.

- For the electric one-touch MulchControl attachment, a switch on the tractor dash is used to engage or disengage mulch mode.

- Changing from mulch mode to side discharge mode or vice versa takes only a few seconds.

MulchControl is well-suited to the following mowing situations:

- Usually mulch, but side discharge when grass gets too long

- Usually side-discharge, but would like to be able to close the chute to control clippings

- Always mulch a main lawn, but often side discharge secondary lawns

- Bag clippings, but want to go farther before emptying bags

MulchControl puts the operator in control of the clippings. The operator can have all the benefits of mulching with the ability to easily change to side discharging or bagging when needed.

While in the side-discharge mode, MulchControl will still mulch about one third of the material. Therefore, the side-discharge mode is essentially a partial-mulch mode. This can be an advantage when side discharging or bagging, as it helps to reduce the amount of material being discharged. Other times this could work as a disadvantage:

- When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high-growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn clean-up is desired

7-bu (247-L) Power Flow rear bagger

Optional rear bagger

Optional rear bagger Power Flow blower

Power Flow blowerAn optional 7-bu (247-L) rear bagger material collection system (MCS) is available. It provides an efficient means of collecting grass clippings and leaves:

- The Power Flow blower and chute are easy to install. The Power Flow blower swings out for easy cleanout and cleanup.

- The hopper design provides modern styling, great bagging performance, cleaner operation, and easy-to-empty bags:

- 7-bu (247-L) capacity

- Easy-to-attach Power Flow blower (ordered separately)

- Easy-to-attach chute (ordered separately)

- Air exhaust duct

- Convenient spring-latch

- Airflow fill indicator

- Quik-Tatch mounting

- Sealed hopper top

- Loose-knit bags available

Larger 14-bu (493-L) and 19-bu (670-L) MCS are available, in addition to the 7-bu (247-L) MCS, for specific X300 and X500 Series Tractor models.

An exclusive 4-year or 300-hour (whichever comes first), single-source, bumper-to-bumper warranty* is standard for all John Deere X300 Series Tractors.

- The warranty is hassle free, with one company handling all of the paperwork.

- Premium features of X300 Series Tractors allow for this longer warranty period, with more coverage than comparable tractors.

*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.

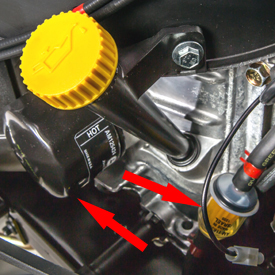

Power steering cylinder

Power steering cylinder Tilt steering lever (X390 and X394 only)

Tilt steering lever (X390 and X394 only)Hydraulic power steering is standard equipment:

- Provides effortless, automotive-like control

- Reduces operator fatigue and increases productivity

- Enables a tight turning radius for great maneuverability

- Adjustable-tilt steering wheel for optimum operator comfort (X390 and X394 Tractor)

Hydraulic lift system is easy to operate

Hydraulic lift

Hydraulic liftThe hydraulic lift control lever is positioned on the dash near the steering wheel for quick, easy, and precise fingertip control of equipment. Implement float, which allows an implement to follow the ground contour, is built into the lift linkage.

Lever-action MulchContol lever

Lever-action MulchContol lever Electric one-touch MulchControl switch

Electric one-touch MulchControl switchLever-action or electric one-touch MulchControl attachment is available for Accel Deep™ 42-in. (107-cm) (42A), 48-in. (122-cm) (48A), and 54-in. (137-cm) (54A) Mower Decks used on X300 and X500 Select Series™ Tractors.

MulchControl advantages and benefits

MulchControl enhances versatility and productivity. A mower deck equipped with MulchControl not only does an excellent job of mowing and mulching, but it can also be quickly converted from side discharging to mulching or vice versa:

- In mulch mode, it controls clippings dispersion in unwanted areas (driveways, landscape beds, near buildings, windows, parking lots, etc.).

- Reduces cleanup time needed to dispose of clippings.

- Reduces the amount of material entering a material collection system because, even in the side discharge mode, MulchControl will mulch about one third of the material due to the additional baffles under the mower deck and the unique design of the mulching blades.

Electric MulchControl has the additional advantage of being controlled from the tractor seat by a switch on the dash to operate an electric actuator that moves the baffle to close off the discharge area of the mower deck.

Electric one-touch MulchControl switch

Electric one-touch MulchControl switch Electric one-touch MulchControl actuator

Electric one-touch MulchControl actuator- Operators can convert between modes without interrupting the mowing process, making it practical to change between modes as conditions require.

- When approaching clean areas like driveways or flowerbeds where clippings would be undesirable

- When a breeze might blow clippings back onto the operator

- For side discharge mowing only the areas of the property where grass is too thick for mulching

- With 48A and 54A Mower Decks, for collecting only the areas of the property where grass is too tall or thick for mulching

- With 48A and 54A Mower Decks, the MulchControl baffle can be opened or closed with the Power Flow™ blower installed. The Power Flow blower will run without material when the baffle is closed.

- Models equipped with a 42A Mower Deck require a MulchControl baffle be removed to install the bagger chute; see 42A Mower Deck versatility explanation for more information.

- Changing from one mode to the other takes only a few seconds.

How MulchControl works

A mower equipped with a MulchControl attachment delivers unprecedented levels of productivity and versatility. The operator has the ability to quickly change between side discharging and mulching. A heavy-duty baffle opens and closes to convert the mower from side discharge mode to mulch mode or vice versa.

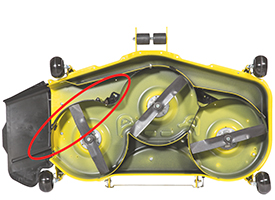

MulchControl baffle open (similar mower deck shown)

MulchControl baffle open (similar mower deck shown) MulchControl baffle closed (similar mower deck shown)

MulchControl baffle closed (similar mower deck shown) MulchControl is an innovative, simple design that is easy to use and maintain:

- The MulchControl attachment includes baffles to control the flow of material under the deck.

- When the MulchControl baffle is open, most of the material flows freely out the discharge deflector or into a material collection system.

- When the MulchControl baffle is closed, material stays within the deck and gets chopped into mulch and deposited in the turf.

MulchControl is well-suited to the following mowing situations:

- For operators who usually mulch, but side discharge when grass gets too long

- For operators who usually side discharge, but would like to be able to close the chute to control clippings in some areas

- For operators who always mulch a main lawn, but often side discharge secondary lawns

- For operators who collect clippings, but want to go farther before emptying the material collection system

MulchControl puts the operator in control of the clippings. The operator can have all the benefits of mulching with the ability to easily change to side discharging when desired.

Advantages of MulchControl include:

- Performance is improved.

- Mulching is beneficial because it returns the clippings to the ground as fertilizer, which promotes lawn growth.

- Clippings are much smaller, which allows them to fall into the grass and be removed from view.

- Unsightly grass clippings are not blown onto driveways or into flower beds.

- Fertilizer use is reduced and provides associated environmental benefits.

- Uptime is increased.

- Operators can convert quickly between modes, making it possible to change between mulching and side discharging as conditions require.

- Mulching heavy, thick material can significantly reduce mower productivity. The ability to switch from mulch to side discharge mode ensures productivity, especially in grass too tall or thick to mulch effectively.

- Cost of operation is reduced.

- Controlling clipping dispersion reduces cleanup time.

MulchControl limitations

While in the side discharge mode, MulchControl will still mulch about one third of the material. Therefore, the side discharge mode is essentially a partial mulch mode. This can be an advantage when side discharging or bagging, as it helps to reduce the amount of material being discharged. Other times this could work as a disadvantage:

- When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn cleanup is desired

- 42A Mower Deck requires a MulchControl baffle be removed to install the bagger chute

MulchControl compatibility

Each MulchControl attachment includes everything needed: baffles and mulch blades for all attachments, and the actuator, wiring, and switches for the electric one-touch attachments.

Lever-action MulchControl attachments

| Attachment number | Description | Applications |

| BM24794 | 42A MulchControl (lever action) | X300 Series Tractors, Z300 Series ZTrak™ Mowers |

| BM24993 | 48A MulchControl (lever action) | X300 and X500 Series Tractors, Z300 and Z500 Series ZTrak Mowers |

| BM24994 | 54A MulchControl (lever action) | X300 and X500 Series Tractors, Z300 and Z500 Series ZTrak Mowers |

Electric one-touch MulchControl attachments

| Attachment number | Description | Applications |

| BUC10164 | 42A electric one-touch MulchControl | X300 Series Tractors* |

| BUC10165 | 48A electric one-touch MulchControl | X300 and X500 Series Tractors* |

| BUC10166 | 54A electric one-touch MulchControl | X300 and X500 Series Tractors* |

* NOTE: Model year 2016-2017 X300 and X500 Series Tractors (X300 serial number 10,001-50,000 and X500 serial number 110,001-130,000) require replacing the tractor wiring harness and dash panel to use an electric MulchControl attachment.

44-in. (112-cm) Front Blade

44-in. (112-cm) Front Blade Snow blower, weather enclosure, and chains on an X300 Series Tractor

Snow blower, weather enclosure, and chains on an X300 Series TractorAn advantage of lawn tractors is their ability to use equipment for snow removal. Lawn tractor owners can add a John Deere snow blower or front blade to make quick work of moving snow whenever the need arises. Weather enclosure and tire-chain attachments add comfort and performance.

Equipment available for snow removal includes:

- 44-in. (112-cm) Snow Blower

- 44-in. (112-cm) Front Blade

- 48-in. (122-cm) Front Blade (X394 Tractor only)

- Tire chains or TerraGrip traction belts

- Weather enclosure (available for all X300 Series, except the X350R)

- Weights

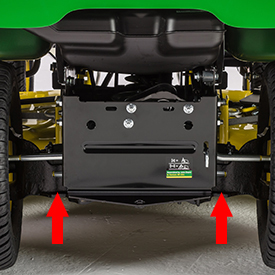

Kanzaki® K46 transaxle (X330, X350, X354) Kansaki K57 transaxle (X370)

Kanzaki® K46 transaxle (X330, X350, X354) Kansaki K57 transaxle (X370) Kanzaki K58 transaxle (X380, X384, X390, X394)

Kanzaki K58 transaxle (X380, X384, X390, X394)The Tuff Torq® hydrostatic transaxle encloses the hydrostatic pump and motor rotator groups in the same housing with the differential and axle housings. This design is very efficient and reduces the number of sealing surfaces to minimize the potential for leakage.

Combined with the foot controls, the hydrostatic transmission functions similarly to that of an automatic transmission in an automobile, so the term automatic is often used to describe it:

- Use of the latest valve designs has significantly reduced the sound level.

- Large pump and motor rotating groups ensure long life and efficient operation.

Freewheeling valve

Freewheeling valve

Freewheeling valve

A freewheeling valve control is conveniently located near the tractor rear hitch plate for good visibility and easy operation.

Kanzaki and Tuff Torq are trademarks of Kanzaki Kokyukoki Manufacturing Company.

Convenient operator station

Convenient operator station Separate throttle and choke controls

Separate throttle and choke controlsThe contoured dash has clean, attractive styling and ergonomic controls for easy use:

- Controls are color coded for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The power take-off (PTO) switch allows the operator to get fingers underneath it, like a T-handle, to pull up for easy activation.

- The reverse implement option (RIO) switch is a yellow button.

- The hydraulic-lift control and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

Functional design of the throttle and choke controls provides good appearance and a comfortable feel.

Easy-to-use key switch and controls

Easy-to-use key switch and controls Tilt steering lever (X390 and X394 only)

Tilt steering lever (X390 and X394 only)- The hydraulic-lift control and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

- Functional design of the throttle and choke controls provides good appearance and a comfortable feel.

- Power steering takes the work out of turns.

- Tilt steering wheel adjusts for operator comfort (X390, X394).

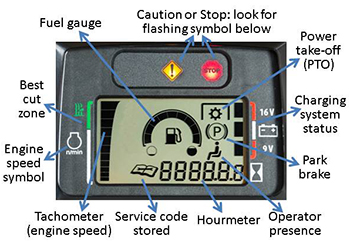

Display panel

Display panel illustration with descriptions

Display panel illustration with descriptions Display panel

Display panelInstrument display has the look and feel of a modern automobile. A power-up sequence cycles lights and gauges to indicate they are working:

- Display features dark-cockpit design to minimize operator distractions.

- Display is back lit for night visibility.

- Night visibility is especially useful with snow blower use.

- Hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Electronic fuel gauge provides real-time fuel level information.

- A tachometer graphically displays engine speed.

- Target-zone graphics inform the operator of the engine speed range to use for best cut quality.

- An indicator tells the operator when the PTO is operating.

- Bright caution and stop lights capture the operator's attention when important information is on the instrument cluster.

- Damage can be prevented and repair costs reduced by addressing problems early.

- Operators are advised of what the problem is if they attempt to operate the mower with unsatisfied PTO, seat, or park brake interlocks.

- The indicators are also useful to identify the reasons the PTO or engine may have shut off when an interlock is unsatisfied.

- Operators are advised if battery voltage is low, normal, or excessive.

- The service indicator light illuminates to indicate a diagnostic error code is stored.

- Onboard diagnostics provides trouble codes for use by trained technicians.

- For example, a technician will be able to test switch functionality and circuit continuity without tools.

- Onboard diagnostics provides trouble codes for use by trained technicians.

Twin Touch™ foot control

Twin Touch foot control

Twin Touch foot control Cruise control

Cruise controlTwin Touch foot pedals control the speed and direction of travel:

- Automotive-type accelerator control ensures easy operation.

- Operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

Cruise control

Cruise control is standard equipment:

- To engage, push the cruise-control button and hold until the foot is removed from the forward pedal.

- For emergency stop, the cruise control can be released by pushing on the brake pedal or the forward pedal.

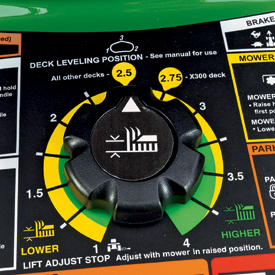

Mower deck height adjustment

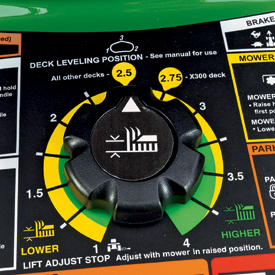

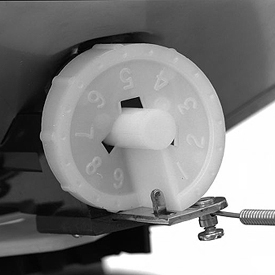

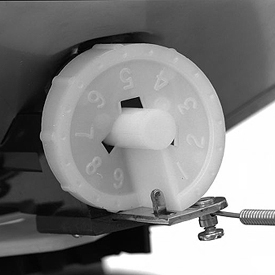

Conveniently-located deck height adjustment knob

Conveniently-located deck height adjustment knob Mower cut-height adjusting knob

Mower cut-height adjusting knob A rotary dial knob makes adjusting the mower cut height quick and easy:

- Provides mower cut heights in 0.25-in. (6.4-cm) increments from 1 in. (2.5 cm) to 4 in. (10.2 cm)

- Returns the mower deck to the same preset height each time it is lowered

Storage tray under tractor seat

Storage tray under tractor seat Exact Adjust tool used to level mower deck

Exact Adjust tool used to level mower deckStorage for the onboard deck-leveling gauge and the Exact Adjust tool is provided in the storage tray under the tractor’s seat.

- Exact Adjust ports allow for easy and accurate leveling of the mower deck for optimum mowing performance.

Deck-leveling gauge placed under deck

Deck-leveling gauge placed under deckDeck-leveling gauge is placed at the appropriate location under the left rear, right rear, and front of the mower deck as the cut height is adjusted using the Exact Adjust tool and front draft arm adjusting nuts.

Parking brake control

Parking brake

Parking brakeDepressing the brake pedal applies internal wet-disk brakes (increased durability and longer life) for safe stopping.

A parking brake control is conveniently located for easy access; it holds the brake pedal securely in locked position.

Electric power take-off (PTO) clutch is easy and convenient to use

Electric PTO switch

Electric PTO switchThe heavy-duty electric PTO clutch is operated with a convenient dash-mounted switch.

Heavy-duty PTO clutch

PTO clutch

PTO clutchThe PTO clutch is designed to operate through many on/off cycles.

Reverse implement option (RIO)

Reverse implement switch

Reverse implement switch Mower engagement power take-off (PTO) switch

Mower engagement power take-off (PTO) switchUsing RIO

CAUTION: Children or bystanders may be injured by rotating blades. Before traveling forward or rearward:

- Carefully check the area around the machine.

- Disengage the mower before backing up.

NOTE: Operating the mower while backing up is strongly discouraged. RIO should be used only when operating another attachment or when the operator deems it necessary to reposition the machine with the mower engaged.

- Stop forward travel. Allow attachment to run.

- Look down and behind the machine to be sure that there are no bystanders.

- Push and hold in the reverse implement switch while depressing the reverse pedal slightly.

NOTE: If the attachment stops while positioning the machine, return mower engagement (PTO) switch to off position. Repeat this procedure from the beginning. - Release the reverse implement switch and reposition the machine as the machine begins to move rearward.

- Resume forward travel. The attachment should continue operating.

- Repeat procedure to position the machine again.

Welded, heavy-duty frame

Welded, heavy-duty frame

The frame is made of heavy formed and welded steel, reinforced in critical areas for even greater strength:

- The frame is formed from 12-gauge, 0.105-in. (2.66-mm) thick material for long life.

- Standard front bumper and hitch plate are formed from 9-gauge, 0.15-in. (3.8-mm) steel and complete the frame assembly.

- Rear hitch plate can support two 42-lb (19-kg) Quik-Tatch weights.

- Weight bracket is built into the frame of two-wheel-steer models.

- Four-wheel-steer models require the optional weight bracket.

Front axle and wheel spindles are heavy-duty

Cast-iron front axle

Cast-iron front axleFront axle is made of nodular cast iron:

- Cast-iron front axle is strong and shock-resistant.

- Cast iron will not yield under heavy loads or impact.

A replaceable bushing is used at axle mounting:

- The bushing provides excellent wear resistance.

- Grease fittings at each spindle are easy to service.

Front steering spindles

Steering spindle

Steering spindleFront steering spindle diameter is 0.75 in. (19 mm) for strength and long life:

- Have strength to handle heavy implements

- Provide long life at bearing surfaces

- Use sealed precision bearings in front wheels

Rear equipment-mounting system is heavy-duty and easy to use

Rear equipment mounting system

Rear equipment mounting systemA heavy-duty equipment mounting system is used:

- Includes strong frame mounts with a combination of mounting holes in the tractor hitch plate that accept pins or shoulder bolts to support heavy rear-mounted equipment.

- Easily attach optional equipment to the tractor

- Can bear the load of heavy rear-mounted equipment, such as material collection systems

Attractive styling

Attractive styling Hood air-intake louvers

Hood air-intake louversSmooth, rounded contours present a modern, styled appearance:

- Hood styling incorporates efficient full-length air-intake louvers on each side, rather than on the top.

- Cooler engine operation

- Lower operator station sound levels

- Hot air is vented out the front grille, away from the operator.

- The fully enclosed hood is made of molded-in-color material.

- Reduces sound

- Will not rust or dent

- Distinctive grille and large, one-piece fender deck complete the styling package.

Two high-quality headlights give excellent visibility

Optimum lighting pattern

Optimum lighting patternHeadlights are standard equipment on all models:

- Two 27-W bulbs provide excellent lighting for good visibility during evening operation.

- A headlight position on the ignition switch makes it easy to operate the headlights.

- The headlights are designed to provide an optimum lighting pattern for mowing and snow removal.

Operator station

Operator station  Operator station

Operator stationThe operator station is designed for operator comfort and ease of using controls:

- A large, 14-in. (36-cm) diameter steering wheel is comfortable to use and minimizes steering effort.

- Full-length foot mats provide comfort for the operator and protect the footrest area.

Comfortable seat

Comfortable open-back seat

Comfortable open-back seat

An open-back 15-in. (38-cm) high-back seat provides a comfortable, smooth ride and good support for the operator:

- Seat travel of 7 in. (18 cm) with 15 positions allows the operator to be seated comfortably and easily operate the controls.

- Seat can be easily adjusted fore and aft by the operator while sitting on the seat.

- Open-back design allows air circulation to keep the operator's back cool and dry for a more comfortable ride.

- Grasp at the top of the seat is conveniently located for use when tilting the seat up to protect it from the weather.

Seat suspension

Seat suspension

Seat suspension

The seat suspension is adjustable, without tools, for the weight of the operator:

- Springs are adjustable fore and aft to any of three positions.

- No tools require

- Allows fine-tuning of the suspension for the operator's weight

- Back position for more support for heavier operators

- Tool tray is designed into the seat base.

- Can be used to store gloves, small tools, etc.

- Provides storage location for Exact Adjust tool and deck-leveling gauge (tool and depth-leveling gauge not shown in photo)

Cup holder

Cup holder and tool tray on fender

Cup holder and tool tray on fenderA cup holder and tool tray are located on the fender for operator convenience:

- The cup holder holds a variety of container sizes.

- Tool tray provides convenient storage.

- Cup holder and tool tray are constructed of durable acrylonitrile butadiene styrene (ABS) plastic.

Removable plug for optional 12-V outlet

Location for optional 12-V outlet

Location for optional 12-V outletA removable plug on the console, in front of the operator, provides a convenient location for the optional 12-V outlet and makes installation easy.

- Convenient for plugging in cell phone charger and other electric devices

- Can be used to operate electric rear equipment, such as a sprayer or spreader

12-V fast connector

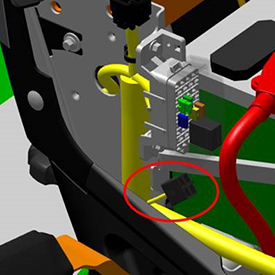

Illustration of fast connector location

Illustration of fast connector locationA mid-vehicle, 12-V fast connector, located under the tractor’s fuse box, is included as standard equipment to reduce initial installation time for some attachments that operate on 12-V power from the tractor:

- The four-cavity connector includes battery, ground, and key switch terminals and is turned on and off with the ignition switch.

One-piece hood is easy to open

One-piece hood is easy to open Service interval decal located under hood

Service interval decal located under hoodThe one-piece hood opens easily to permit checking and servicing the engine:

- Important service points are located within easy reach.

- A service-interval decal is provided inside the tractor hood for convenience when servicing the tractor.

- The high-quality engine used in the X300 Series does not require an 8-hour oil and filter change because improvements in the manufacturing process and quality of parts, components, and oils have eliminated the need for the short interval oil change requirement.

Easy-to-service engine fuel and oil filters

Easy-to-service engine fuel and oil filtersThe engine fuel and oil filters, the oil check/fill tube, and the oil drain tube are exposed for serviceability when the hood is opened.

Exact Adjust ports and onboard deck-leveling tools make precise deck adjustments easy

Deck-leveling gauge and hex adjusting tool stored under tractor seat

Deck-leveling gauge and hex adjusting tool stored under tractor seat Exact Adjust access holes

Exact Adjust access holesA mower deck must be level side-to-side and properly adjusted front-to-rear to give the best cutting performance. A removable onboard deck-leveling gauge and a hex-key tool are provided to make adjustment easy. They are securely stored under the tractor seat.

Exact Adjust leveling ports are provided on each side of the operator platform above the mower-level adjusting bolts. With the hex-shaped tool, they provide convenient access to allow quick and easy adjustment of the mower for the best-cut quality of cut.

The Exact Adjust feature is standard on all Select Series™ X300 and X500 Tractors:

- There is no need to reach under the fender deck while making the mower-level adjustment.

- Onboard deck-leveling gauge, Exact Adjust ports, and the hex tool work together.

- Level the mower deck side to side

- Set the correct amount of rake (front-to-back deck orientation)

- Calibrate the cutting height to the cut-height adjusting knob setting

- Exact Adjust simplifies leveling the mower deck if equipped with a Power Flow™ blower.

- To give the best cut, mower level should be adjusted if alternately mowing with and without blower installed. The Exact Adjust feature makes this easy.

Deck-leveling tool placed under deck

Deck-leveling tool placed under deck Using included ball-hex tool to level mower deck

Using included ball-hex tool to level mower deckConsult the operator's manual for the correct adjusting procedures for each tractor model. Basic adjusting steps to properly level the mower deck include:

- Park the tractor on a level surface.

- Inflate tires to the correct pressure.

- Consult the label for the cutting-height knob that is located on the console of the machine. This label shows deck-leveling position and location of deck-leveling adjustment points.

Cut height adjusting knob

Cut height adjusting knob- Set mower cutting-height knob to the correct deck-leveling position.

- For X300 models, use position 2.75

- For all other models, use position 2.5

- Adjust mower wheels as necessary so they do not contact the ground surface.

- Remove the onboard deck-leveling gauge that is located under the seat.

- Using the Exact Adjust ports and tool, adjust mower deck side-to-side level so the deck-leveling gauge just slips under the left and right lower deck rim at the designated adjustment points. The location of adjustment points will vary slightly between decks.

- Left- and right-rear adjustment points are under the deck rim near the rear mower wheels, if equipped.

- Adjust mower deck front-to-back level, if necessary.

- Loosen rear nuts equally on each side of front lift rod.

- Turn front nut equally on each side clockwise to raise front of mower or counterclockwise to lower it until gauge just slips under the front adjustment point.

- Tighten rear nuts after adjustment is complete.

- Return the gauge to its storage position.

NOTE: The adjusting tool supplied with the tractor is an 8-mm ball-hex key, part number M162737. The rounded end allows for some misalignment with the bolt as the deck is adjusted.

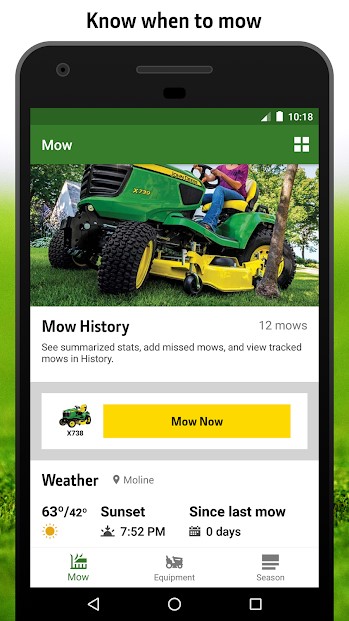

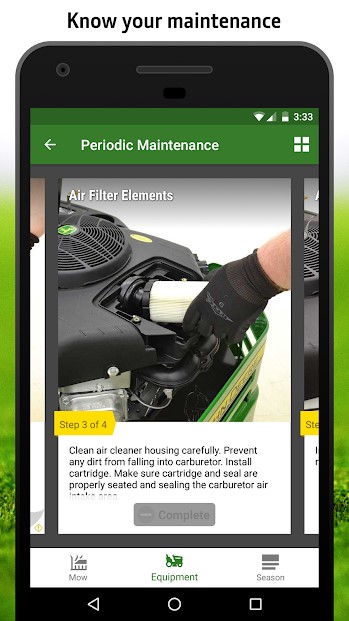

MowerPlus app screen

MowerPlus app screen MowerPlus app maintenance screen

MowerPlus app maintenance screenKeep a John Deere riding lawn mower running its best and know how it mows with the John Deere MowerPlus app. Simply scan the lawn tractor’s barcode to get custom information. The app helps determine the best time to mow, communicates expert pre-mow tips, offers maintenance reminders, and provides walk-through guides.

Look for the MowerPlus app on the mobile device’s app store.

The app supports residential lawn equipment such as 100 Series, S240, X300, X500, X700, Z200 through Z600, and many similarly-sized older products. It does not presently support tractor models numbered 1000 and larger, such as 1025R.

NOTE: Some product image variation may exist.

Also available is the John Deere MowerPlus smart connector (sold separately).

Smart connector

Smart connectorThe John Deere MowerPlus smart connector wirelessly links a Select Series™ X300 or X500 Tractor to the MowerPlus app on a mobile device. The smart connector transmits engine usage to the app, making it easy to track maintenance intervals. It also transmits the fuel level to the app—when thinking ahead about Saturday morning mowing, the operator can make sure the tractor is fueled and ready to go.

Specifications

| Key Specs | x390-lawn-tractor-48-in Current Model |

|---|---|

| Engine power | 22 hp 16.4 kW |

| Engine manufacturer/model | FS651V |

| Transaxle type | K58 hydrostatic integrated with transaxle |

| Transaxle control | Twin Touch™ pedals |

| Rear tires | 22x11-10 |

| Steering type | Power, hydraulic |

| Lift system type | Hydraulic |

| Cutting width | Accel Deep™ mower deck, 48 in. 122 cm |

| U.S. warranty | 4 year/300 hour bumper-to-bumper* (*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.) |

| Engine | |

| Power | 22 hp 16.4 kW |

| Displacement | 44.3 cu in. 726 cc |

| Manufacturer/model | FS651V |

| Type | Overhead valve, full-pressure lube, oil filter |

| Cylinders | V-twin, cast-iron liners |

| Governor | Mechanical |

| Choke/speed control | Separate levers, automatic choke return |

| Cooling method | Air |

| Air cleaner | Dry, replaceable with foam precleaner |

| Oil drain | No tools |

| Fuel system | |

| Type | Gasoline |

| Fuel delivery | Pulse pump, carburetor |

| Fuel gauge | Gauge on dash |

| Fuel tank location | Rear |

| Fuel fill opening | On left fender, 3 in. 7.6 cm |

| Fuel tank capacity | 3.3 U.S. gal. 12.5 L |

| Electrical system | |

| Battery | 12 V 340 CCA |

| Charging system | Flywheel alternator, regulated, 15 amp |

| Engine starter | Bendix |

| Hourmeter | Yes |

| Headlights | Two standard, incandescent, 27 W |

| Taillights or reflector | No |

| Backup lights | No |

| Rear work lights | No |

| 12-V outlet | Optional |

| Transaxle | |

| Type | K58 hydrostatic integrated with transaxle |

| Control | Twin Touch™ pedals |

| Cruise control | Yes, button on dash |

| Oil cooler | Fins and fan on transaxle |

| Oil filter | Internal, not replaceable |

| Differential lock | No |

| Forward speed | 0-6.2 mph 0-10 km/h |

| Reverse speed | 0-3.5 mph 0-5.6 km/h |

| Brakes | Internal wet disc |

| Chassis | |

| Frame | Welded heavy-duty |

| Primer/paint | E-coat/powder |

| Weight bracket | Standard rear, optional front |

| Receiver hitch | No |

| Front axle | Cast iron front axle, front wheel ball bearings |

| Spindle bushings | Metal, replaceable |

| Front tires | 15x6.5-8 |

| Rear tires | 22x11-10 |

| Hood material | Molded-in color hood material reduces sound, will not rust or dent |

| Fender deck material | Stamped steel |

| Floor mats | Sure-grip rubber |

| Storage | On fender and under seat |

| Service interval decal | Yes |

| Fender handles/grips | No |

| Cup holder | Yes |

| Equipment mounting | Yes, heavy duty |

| Steering | |

| Type | Power, hydraulic |

| Four-wheel steer | Not available on this model |

| Steering wheel | Large, 14 in. 35.6 cm |

| Tilt steering wheel | Standard, five position |

| Turning radius | 22 in. 55.9 cm |

| Uncut circle radius | 24 in. 61 cm |

| Seat | |

| Type | Open-back design with grasp |

| Seat back height | 15 in. 38.1 cm |

| Armrests | No |

| Fore-aft adjustment | While seated, slide rail, 14-position, 7 in. 17.8 cm |

| Seat suspension | Tilt, two coil springs, three-position no-tools adjustment for operator weight |

| Lift system | |

| Type | Hydraulic |

| Hydraulic outlets | No |

| Mower cut height | 13 positions, 1-4 in. 2.5-10.2 cm |

| Cut height increments | 0.25 in. 0.64 cm |

| Preset cut height | Yes |

| Mower deck | |

| Type | Side discharge |

| Cutting width | Accel Deep™ mower deck, 48 in. 122 cm |

| Construction | Stamped steel deck shell |

| Mower deck material | 10 gauge 0.135 in. 3.4 mm |

| Mower wash port | Yes |

| Mower drive system | Electric power take-off (PTO) clutch, in-line belt |

| Mower wheels | Four |

| Mower wheel adjustment | Seven-position, spring-loaded pin |

| Mower level adjustment | Exact Adjust ports and onboard deck-leveling gauge |

| Mower attachability | |

| Type | Roll under tractor |

| Front draft arms | Attached with spring pins at two points |

| Rear draft arms | Quick-pull pins |

| Mower wheels rotate | Yes, 90 degrees for easy mower removal |

| Drive system | Dual belt |

| Safety | |

| Meets ANSI standard | Yes |

| Meets OPEI standard | Yes |

| Backup protection | Reverse Implement Option (RIO) |

| Safety video | Yes |

| Buyer's notes | |

| Notes | Hydraulic power lift for superior convenience and ease of use Power steering with tilt steering wheel for exceptional maneuverability and comfort One-piece hood for easy service access, molded-in color hood material reduces sound and will not rust or dent |

| Warranty | 4 year/300 hour bumper-to-bumper* (*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.) |

| Optional equipment | |

| Mowers | 48A (standard) |

| Rear bagger | 7, 19 bu 247, 670 L |

| Powered material collection | Power Flow™ blower |

| Mulching system | Yes, MulchControl™ |

| Front thatcher | 38, 46, 54 in. 96.5, 116.8, 137.2 cm |

| Front blade | 44 in. 111.8 cm |

| Mid-mount blade | |

| Snow blower | Two-stage, 44 in. 111.8 cm |

| Rotary broom | |

| Rotary tiller | |

| Sleeve hitch | |

| 3-point hitch | |

| Rear power take-off (PTO) | |

| Plow, moldboard | |

| Box scraper | |

| Cultivator | |

| Rear blade | |

| Disk harrow | |

| Landscape rake | |

| Sprayer | Tow-behind, 15 U.S. gal. 56.8 L Tow-behind, 25 U.S. gal. 94.6 L Mounted, 25 U.S. gal. |

| Spreader | Tow-behind, 125 lb 57.7 kg Tow-behind, 175 lb 79.4 kg Mounted, 125 lb |

| Front bumper | Styled bumper option |

| Brush guard | Yes |

| Weather protection | Weather enclosure |

| Sun canopy | Yes |

| Rear receiver hitch | |

| Bucket holder | Yes, double bucket |

| Grass striping | Lawn striping kit |

| Tractor shovel | 40 in. 101.6 cm |

| Front loader | |

| Other equipment | |

| Tow-behind tools | 16 |

| Dimensions | |

| Height | 47 in. 120 cm |

| Overall length | 72 in. 182.9 cm |

| Wheelbase | 49.4 in. 125.5 cm |

| Width with mower | 62.5 in. 159 cm |

| Width with mower (deflector raised for storage) | 53.6 in. 136 cm |

| Width without mower | 38.5 in. 97.5 cm |

| Weight | Mower, no fuel, 678 lb 308 kg |

Accessories and Attachments

Carts

7P Poly Utility Cart

7P Poly Utility Cart

Every owner of a John riding lawn and garden product is a potential customer for a high-quality, affordable utility cart. Utility carts can be used to haul a variety of materials including firewood, lawn debris, sand, dirt, mulch, garden tools, plants, and bushes.

Utility carts are designed, painted, and decaled to be compatible with other John Deere equipment.

NOTE: For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak™ or ZTrak™ mower should not exceed 250 lb (113.4 kg). See the appropriate vehicle pages for the weight of the vehicle and the mower deck.

7P Poly Utility Cart

7P Poly Utility Cart- The cart has a premium molded, high-density polyethylene box construction.

- Compression molding process allows polyethylene to be the optimum thickness in all areas for superior strength and durability.

- Polyethylene body will not rust or dent; it stays looking new longer.

- 0.75-in. (2-cm) x 2-in. (5-cm) stake pockets are molded in to make the addition of side extensions easy.

- Two vertical 0.75-in. (2-cm) molded channels on each side allow easy use of dividers to separate the box into two or three compartments.

- Ribs in the box bottom add strength and prevent the shovel from hitting bolts when emptying the cart.

- Sloped tailgate design makes emptying the box easier; there is no tailgate to loosen or remove.

- Styling is compatible with other John Deere equipment.

- Pneumatic tires provide turf tread for good flotation, shock absorption, and minimal rolling resistance.

Wheels

7P Utility Cart wheel

7P Utility Cart wheel

Wheels are mounted on a solid, one-piece axle for durability.

Iron and Oilite® wheel bearings with grease fittings provide lubrication for long life.

The pneumatic tires offer the following:

- Good flotation

- Minimal rolling resistance

- Shock absorption

Sloped tailgate

Sloped tailgate for easy emptying

Sloped tailgate for easy emptyingA sloped tailgate design makes emptying the box easier; there is no tailgate to loosen or remove.

Tractor hitch

Spring-pin tractor hitch

Spring-pin tractor hitchA large-diameter hitch pin provides plenty of strength:

- Fast, easy attachment to the tractor hitch

- Spring pin to ensure the pin stays in place

Tilt latch

Tilt latch

Tilt latchAn easy-to-use, spring-loaded dump latch allows tilting the box for easier unloading. A steep dump angle makes emptying the cart easier.

Model comparison chart

Comparison with similar models

| Model | Order through | Box capacity (heaped) | Material thickness | Maximum weight | Vehicle compatibility |

| 7P | Order Zone | 7 cu ft (0.20 m3) | High-density polyethylene (HDPE)** | 450 lb* (204 kg) | EZtrak, ZTrak, 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 8Y | Order Zone | 8 cu ft (0.22 m3) | HDPE** | 300 lb* (136 kg) (tow) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 10P | Order Zone | 10 cu ft (0.28 m3) | Polypropylene | 650 lb* (295 kg) | EZtrak, ZTrak, 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 13 | Order Zone | 13 cu ft (0.37 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 16YS | Order Zone | 17 cu ft (0.48 m3) | Polypropylene | 800 lb (363 kg), 350 lb (158 kg) when using swivel feature to dump | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 17P | Order Zone | 17 cu ft (0.48 m3) | Polypropylene | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 18 | Order Zone | 18 cu ft (0.51 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 21 | Order Zone | 21 cu ft (0.59 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | X700 Series |

*The total weight of the cart and payload. For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). The maximum weight for the 21 Utility Cart is rated at 20 mph (32.2 km/h).

**HDPE is compression molded for optimum thickness in all areas and maximum durability.

Specifications

7P | 8Y | 10P | 13 | 16YS | 17P | 18 | 21 | |

| Box capacity | ||||||||

| Heaped | 7 cu ft (0.20 m3) | 8 cu ft (0.22 m3) | 10 cu ft (0.28 m3) | 13 cu ft (0.37 m3) | 17 cu ft (0.48 m3) | 17 cu ft (0.48 m3) | 18 cu ft (0.51 m3) | 21 cu ft (0.59 m3) |

| Struck | 5.6 cu ft (0.16 m3) | 6.6 cu ft (0.19 m3) | 8.3 cu ft (0.24 m3) | 10 cu ft (0.28 m3) | 15 cu ft (0.42 m3) | 14 cu ft (0.40 m3) | 15 cu ft (0.42 m3) | 15 cu ft (0.42 m3) |

| Maximum weight | 450 lb* (204 kg) | 300 lb* (136 kg) | 650 lb* (295 kg) | 1,000 lb* (454 kg) | 800 lb* (363 kg), 350 lb (158 kg) when using swivel feature to dump | 1,000 lb* (454 kg) | 1,000 lb* (454 kg) | 1,000 lb* (454 kg) |

| Box dimensions | ||||||||

| Width | 33 in. (84 cm) | 33.68 in. (85.5 cm) | 30.3 in. (77 cm) | 30.25 in. (76.8 cm) | 39.5 in. (100.3 cm) | 39.5 in. (100.3 cm) | 38 in. (96.5 cm) | 48 in. (122 cm) |

| Length | 45 in. (114 cm) | 45 in. (114 cm) | 44.5 in. (113 cm) | 48 in. (122 cm) | 58.5 in. (148.6 cm) | 58.5 in. (148.6 cm) | 48 in. (122 cm) | 48 in. (122 cm) |

| Depth | 10.5 in. (27 cm) | 10.75 in. (27.3cm) | 12 in. (30.5 cm) | 12 in. (30.5 cm) | 15.5 in. (39.4 cm) | 15.5 in. (39.4 cm) | 18 in. (45.7 cm) | 11 in. (27.9 cm) |

| Box construction | Molded | Molded | Molded | Welded | Molded | Molded | Welded | Bolted |

| Material | High-density polyethylene (HDPE)** | HDPE** w/UV inhibitor | Polypropylene | 16-gauge, 0.06-in. (1.5-mm) steel | Polypropylene | Polypropylene | 16-gauge, 0.06-in. (1.5-mm) steel | 16-gauge, 0.06-in. (1.5-mm) steel |

| Tailgate | None, sloped | None, sloped | None, sloped | Hinged | None, sloped | None, sloped | Hinged | Lift-out/swing-out |

| Pneumatic tires | 2 ply | --- | 2 ply | 2 ply | 4 ply | 4 ply | 4 ply | 2 ply |

| Size | 13x4-6 | 13x4-6 | 15x6.00-6 | 15x6.00-6 | 16x6.50-8 | 16x6.50-8 | 16x6.50-8 | 20x10.00-8 |

| Tread design | Turf | Knobby | Turf | Turf | Turf | Turf | Turf | Turf |

| Recommended inflation pressure | 30 psi (207 kPa) | 30 psi (207 kPa) | 14 psi (97 kPa) | 14 psi (97 kPa) | 35 psi (241 kPa) | 28 psi (193 kPa) | 28 psi (193 kPa) | 10 psi (70 kPa) |

| Wheel bearings | Iron/Oilite | None | Iron/Oilite | Iron/Oilite | Iron/Oilite | Iron/Oilite | Iron/Oilite | Ball bearings, double sealed |

| Grease fittings on wheels | Yes | None | Yes | Yes | Yes | Yes | Yes | None |

| Axle diameter | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 1 in. (2.54 cm) | 1 in. (2.54 cm) |

| Ground clearance | 5.62 in. (14.3 cm) | 5.25 in. (13.3 cm) | 6.5 in. (16.5 cm) | 6.5 in. (16.5 cm) | 14.25 in. (36.2 cm) | 14.25 in. (36.2 cm) | 7 in. (17.8 cm) | 8.25 in. (21 cm) |

| Width, overall | 34 in. (86.4 cm) | 33.68 in. (85.5 cm) | 38 in. (96.5 cm) | 38 in. (96.5 cm) | 39.5 in. (100.3 cm) | 39.5 in. (100.3 cm) | 38 in. (96.5 cm) | 48 in. (122 cm) |

| Hitch pin | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip |

| Dump angles | 55 degrees | 55 degrees | 56 degrees | 31 degrees | 46 degrees | 46 degrees | 35/40 degrees | 35/40 degrees |

| Maximum tongue weight | 100 lb (45.4 kg) | 100 lb (45.4 kg) | 70 lb (31.75 kg) | 100 lb (45.4 kg) | 50 lb (22 kg) | 100 lb (45.4 kg) | 100 lb (45.4 kg) | 100 lb (45.4 kg) |

| Shipping weight with carton | 68 lb (31 kg) | 65 lb (29.5 kg) | 79 lb (35.8 kg) | 110 lb (49.9 kg) | --- | 105 lb (47.6 kg) | 170 lb (77.1 kg) | 240 lb (109 kg) |

| Net weight | 65 lb (29 kg) | 55 lb (25 kg) | 72 lb (32.7 kg) | 105 lb (47.6 kg) | 103 lb (47 kg) | 105 lb (47.6 kg) | 150 lb (68 kg) | 220 lb (99.8 kg) |

*Total weight of the cart and payload. For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg).

**HDPE is compression molded for optimum thickness in all areas and maximum durability.

Tractor compatibility and requirements

Utility Carts

Chart below shows vehicle compatibility.

An X indicates cart can be used with the pulling unit.

NOTE: For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). The chart shows which utility carts are compatible with the vehicle.

| 7P | 8Y | 10P | 13 | 16YS | 17P | 18 | 21 | |

| EZtrak Z225, Z235, Z245, Z255, Z425, Z435, Z445, Z465, Z625, Z645, Z655, Z665 ZTrak Z335E, Z355E, Z335M, Z345M, Z345R, Z355R, Z375R, Z525E, Z535M, Z540M, Z535R, Z540R, Z720E, Z735E, Z730M, Z735M, Z740R | X | X | ||||||

| L100, L108, L110, L111, L118, L120, L130 102, 115, 125, 135, 145, 155C, 190C, LA100, LA110, LA120, LA130, LA140, LA150, LA105, LA115, LA125, LA135 LE, LA135 SE, LA145, LA155, LA165, LA175, D100, D105, D110, D120, D125, D130, D140, D150, D155, D160, D170, E100, E110, E120, E130, E140, E150, E160, E170, E180 | X | X | X | X | X | X | X | |

| S240 | X | X | X | X | X | X | X | |

| LT150, LT160, LT180, LT190, LTR180 | X | X | X | X | X | |||

| LX280, LX280AWS, LX289 | X | X | X | X | X | |||

| X300, X300R, X304, X310, X320, X324, X340, X360, X330, X350, X350R, X354, X370, X380, X384, X390, X394 | X | X | X | X | X | X | X | |

| SST15, SST16, SST18 | X | X | X | |||||

| G110 | X | X | X | X | X | X | ||

| GT235, GT245 | X | X | X | X | X | X | ||

| GX255, GX335, GX345, GX355 | X | X | X | X | X | X | ||

| X500, X520, X530, X534, X540 X570, X580, X584, X590 | X | X | X | X | X | X | X | |

| X465, X475, X485, X495, X575, X585, X595 | X | X | X | X | X | X | X | X |

| X700, X720, X724, X728, X729, X740, X744, X748, X749 X710, X730, X734, X738, X739, X750, X754, X758 | X | X | X | X | X | X | X | X |

For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). See the appropriate vehicle pages for the weight of the vehicle and the mower deck. Additional weight can be added to the vehicle by the following methods:

| Tractor | Additional weight |

| L100, L108, L110, L111, L118, L120, L130 102, 115, 125, 135, 145, 155C, 190C, LA100, LA110, LA120, LA130, LA140, LA150, LA105, LA115, LA125, LA135 LE, LA135 SE, LA145, LA155, LA165, LA175, D100, D105, D110, D120, D130, D140, D150, D155, D160, D170, E100, E110, E120, E130, E140, E150, E160, E170, E180 | Two 30-lb (14-kg) wheel weights, front Two 42-lb (19-kg) suitcase weights, rear |

| S240 | Two 34-lb (15-kg) wheel weights, front (4) 42-lb (19-kg) suitcase weights, rear |

| LT150, LT160, LT180, LT190, LTR180 | Two 34-lb (15-kg) wheel weights, front Two 31-lb (14.1-kg) plastic shell wheel weights, rear (not for LT190) |

| LX280, LX280AWS, LX289 X300, X300R, X304, X310, X320, X324, X340, X360 X330, X350, X350R, X354, X370, X380, X384, X390, X394 | Two 34-lb (15-kg) wheel weights, front Four 42-lb (19-kg) suitcase weights, rear |

| SST15, SST16, SST18 | One 88-lb (40-kg) weight kit, front Three 40-lb (18-kg) weights, rear |

| G100 | Two 50-lb (23-kg) wheel weights, rear Two 42-lb (19-kg) suitcase weights, rear |

| G110 | Two 50-lb (23-kg) plastic shell rear wheel weights |

| GT235, GT245 | Two 30-lb (14-kg) wheel weights, front Four 42-lb (19-kg) suitcase weights, front Four 42-lb (19-kg) suitcase weights, rear Four 50-lb (23-kg) wheel weights, rear Two 50-lb (23-kg) plastic shell wheel weights, rear |

| GX255, GX335, GX345, GX355 X500, X520, X530, X534, X540 X570, X580, X584, X590 | Two 30-lb (14-kg) wheel weights, front Four 42-lb (19-kg) suitcase weights, front Four 42-lb (19-kg) suitcase weights, rear Four 50-lb (23-kg) wheel weights, rear Two 50-lb (23-kg) wheel plastic shell weights, rear |

X465, X475, X485, X495, X575, X585, X595 | Four 42-lb (19-kg) suitcase weights, front Two 70-lb (32-kg) wheel cast-iron starter weights, rear Four 50-lb (23-kg) cast-iron wheel weights, rear Two 50-lb (23-kg) plastic shell wheel weights, rear Six 42-lb (19-kg) suitcase weights, rear |

Ordering information

Please contact a local John Deere dealer for availability and pricing information.

7P Poly Utility Cart

Order number: LP21935

Oilite is a trademark of Beemer Precision, Incorporated.

8Y Convertible Poly Utility Cart, push mode

8Y Convertible Poly Utility Cart, push mode 8Y Convertible Poly Utility Cart, tow-behind mode

8Y Convertible Poly Utility Cart, tow-behind mode The 8-cu-ft (0.23-m3), 300-lb (136-kg) capacity 8Y Convertible Poly Utility Cart can be used to haul a variety of materials including lawn debris, sand, dirt, mulch, and plants. The unique convertible hitch allows changing the cart from tow-behind mode to push mode without tools.

Key features include:

- Compatible with riding lawn tractors and garden tractors

- Durable poly construction

- All-terrain pneumatic tires

- Converts from tow cart to push cart without tools

- Large handle is provided for ease of use

Every owner of a John Deere riding lawn and garden product is a potential customer for a high-quality, affordable utility cart. Utility carts can be used to haul a variety of materials including firewood, lawn debris, sand, dirt, mulch, garden tools, plants, and bushes. Utility carts are designed, painted, and decaled to be compatible with other John Deere equipment.

NOTE: For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. See the appropriate vehicle pages for the weight of the vehicle and the mower deck.

Model comparison chart

Comparison with similar models

| Model | Order through | Box capacity (heaped) | Material thickness | Maximum weight | Vehicle compatibility |

| 7P | Order Zone | 7 cu ft (0.20 m3) | High-density polyethylene (HDPE)** | 450 lb* (204 kg) | EZtrak™, ZTrak™, 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 8Y | Order Zone | 8 cu ft (0.22 m3) | HDPE** | 300 lb* (136 kg) (tow) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 10P | Order Zone | 10 cu ft (0.28 m3) | Polypropylene | 650 lb* (295 kg) | EZtrak, ZTrak, 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 13 | Order Zone | 13 cu ft (0.37 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 16YS | Order Zone | 17 cu ft (0.48 m3) | Polypropylene | 800 lb (363 kg), 350 lb (158 kg) when using swivel feature to dump | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 17P | Order Zone | 17 cu ft (0.48 m3) | Polypropylene | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 18 | Order Zone | 18 cu ft (0.51 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 21 | Order Zone | 21 cu ft (0.59 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | X700 Series |

*The total weight of the cart and payload. For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). The maximum weight for the 21 Utility Cart is rated at 20 mph (32.2 km/h).

**HDPE is compression molded for optimum thickness in all areas and maximum durability.

Specifications

7P | 8Y | 10P | 13 | 16YS | 17P | 18 | 21 | |

| Box capacity | ||||||||

| Heaped | 7 cu ft (0.20 m3) | 8 cu ft (0.22 m3) | 10 cu ft (0.28 m3) | 13 cu ft (0.37 m3) | 17 cu ft (0.48 m3) | 17 cu ft (0.48 m3) | 18 cu ft (0.51 m3) | 21 cu ft (0.59 m3) |

| Struck | 5.6 cu ft (0.16 m3) | 6.6 cu ft (0.19 m3) | 8.3 cu ft (0.24 m3) | 10 cu ft (0.28 m3) | 15 cu ft (0.42 m3) | 14 cu ft (0.40 m3) | 15 cu ft (0.42 m3) | 15 cu ft (0.42 m3) |

| Maximum weight | 450 lb* (204 kg) | 300 lb* (136 kg) | 650 lb* (295 kg) | 1,000 lb* (454 kg) | 800 lb* (363 kg), 350 lb (158 kg) when using swivel feature to dump | 1,000 lb* (454 kg) | 1,000 lb* (454 kg) | 1,000 lb* (454 kg) |

| Box dimensions | ||||||||

| Width | 33 in. (84 cm) | 33.68 in. (85.5 cm) | 30.3 in. (77 cm) | 30.25 in. (76.8 cm) | 39.5 in. (100.3 cm) | 39.5 in. (100.3 cm) | 38 in. (96.5 cm) | 48 in. (122 cm) |

| Length | 45 in. (114 cm) | 45 in. (114 cm) | 44.5 in. (113 cm) | 48 in. (122 cm) | 58.5 in. (148.6 cm) | 58.5 in. (148.6 cm) | 48 in. (122 cm) | 48 in. (122 cm) |

| Depth | 10.5 in. (27 cm) | 10.75 in. (27.3cm) | 12 in. (30.5 cm) | 12 in. (30.5 cm) | 15.5 in. (39.4 cm) | 15.5 in. (39.4 cm) | 18 in. (45.7 cm) | 11 in. (27.9 cm) |

| Box construction | Molded | Molded | Molded | Welded | Molded | Molded | Welded | Bolted |

| Material | High-density polyethylene (HDPE)** | HDPE** w/UV inhibitor | Polypropylene | 16-gauge, 0.06-in. (1.5-mm) steel | Polypropylene | Polypropylene | 16-gauge, 0.06-in. (1.5-mm) steel | 16-gauge, 0.06-in. (1.5-mm) steel |

| Tailgate | None, sloped | None, sloped | None, sloped | Hinged | None, sloped | None, sloped | Hinged | Lift-out/swing-out |

| Pneumatic tires | 2 ply | --- | 2 ply | 2 ply | 4 ply | 4 ply | 4 ply | 2 ply |

| Size | 13x4-6 | 13x4-6 | 15x6.00-6 | 15x6.00-6 | 16x6.50-8 | 16x6.50-8 | 16x6.50-8 | 20x10.00-8 |

| Tread design | Turf | Knobby | Turf | Turf | Turf | Turf | Turf | Turf |

| Recommended inflation pressure | 30 psi (207 kPa) | 30 psi (207 kPa) | 14 psi (97 kPa) | 14 psi (97 kPa) | 35 psi (241 kPa) | 28 psi (193 kPa) | 28 psi (193 kPa) | 10 psi (70 kPa) |

| Wheel bearings | Iron/Oilite | None | Iron/Oilite | Iron/Oilite | Iron/Oilite | Iron/Oilite | Iron/Oilite | Ball bearings, double sealed |

| Grease fittings on wheels | Yes | None | Yes | Yes | Yes | Yes | Yes | None |

| Axle diameter | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 0.75 in. (1.905 cm) | 1 in. (2.54 cm) | 1 in. (2.54 cm) |

| Ground clearance | 5.62 in. (14.3 cm) | 5.25 in. (13.3 cm) | 6.5 in. (16.5 cm) | 6.5 in. (16.5 cm) | 14.25 in. (36.2 cm) | 14.25 in. (36.2 cm) | 7 in. (17.8 cm) | 8.25 in. (21 cm) |

| Width, overall | 34 in. (86.4 cm) | 33.68 in. (85.5 cm) | 38 in. (96.5 cm) | 38 in. (96.5 cm) | 39.5 in. (100.3 cm) | 39.5 in. (100.3 cm) | 38 in. (96.5 cm) | 48 in. (122 cm) |

| Hitch pin | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip | Pin/spring clip |

| Dump angles | 55 degrees | 55 degrees | 56 degrees | 31 degrees | 46 degrees | 46 degrees | 35/40 degrees | 35/40 degrees |

| Maximum tongue weight | 100 lb (45.4 kg) | 100 lb (45.4 kg) | 70 lb (31.75 kg) | 100 lb (45.4 kg) | 50 lb (22 kg) | 100 lb (45.4 kg) | 100 lb (45.4 kg) | 100 lb (45.4 kg) |

| Shipping weight with carton | 68 lb (31 kg) | 65 lb (29.5 kg) | 79 lb (35.8 kg) | 110 lb (49.9 kg) | --- | 105 lb (47.6 kg) | 170 lb (77.1 kg) | 240 lb (109 kg) |

| Net weight | 65 lb (29 kg) | 55 lb (25 kg) | 72 lb (32.7 kg) | 105 lb (47.6 kg) | 103 lb (47 kg) | 105 lb (47.6 kg) | 150 lb (68 kg) | 220 lb (99.8 kg) |

*Total weight of the cart and payload. For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg).

**HDPE is compression molded for optimum thickness in all areas and maximum durability.

Tractor compatibility and requirements

Utility Carts

Chart below shows vehicle compatibility.

An X indicates cart can be used with the pulling unit.

NOTE: For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). The chart shows which utility carts are compatible with the vehicle.

| 7P | 8Y | 10P | 13 | 16YS | 17P | 18 | 21 | |

| EZtrak Z225, Z235, Z245, Z255, Z425, Z435, Z445, Z465, Z625, Z645, Z655, Z665 ZTrak Z335E, Z355E, Z335M, Z345M, Z345R, Z355R, Z375R, Z525E, Z535M, Z540M, Z535R, Z540R, Z720E, Z735E, Z730M, Z735M, Z740R | X | X | ||||||

| L100, L108, L110, L111, L118, L120, L130 102, 115, 125, 135, 145, 155C, 190C, LA100, LA110, LA120, LA130, LA140, LA150, LA105, LA115, LA125, LA135 LE, LA135 SE, LA145, LA155, LA165, LA175, D100, D105, D110, D120, D125, D130, D140, D150, D155, D160, D170, E100, E110, E120, E130, E140, E150, E160, E170, E180 | X | X | X | X | X | X | X | |

| S240 | X | X | X | X | X | X | X | |

| LT150, LT160, LT180, LT190, LTR180 | X | X | X | X | X | |||

| LX280, LX280AWS, LX289 | X | X | X | X | X | |||

| X300, X300R, X304, X310, X320, X324, X340, X360, X330, X350, X350R, X354, X370, X380, X384, X390, X394 | X | X | X | X | X | X | X | |

| SST15, SST16, SST18 | X | X | X | |||||

| G110 | X | X | X | X | X | X | ||

| GT235, GT245 | X | X | X | X | X | X | ||

| GX255, GX335, GX345, GX355 | X | X | X | X | X | X | ||

| X500, X520, X530, X534, X540 X570, X580, X584, X590 | X | X | X | X | X | X | X | |

| X465, X475, X485, X495, X575, X585, X595 | X | X | X | X | X | X | X | X |

| X700, X720, X724, X728, X729, X740, X744, X748, X749 X710, X730, X734, X738, X739, X750, X754, X758 | X | X | X | X | X | X | X | X |

For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). See the appropriate vehicle pages for the weight of the vehicle and the mower deck. Additional weight can be added to the vehicle by the following methods:

| Tractor | Additional weight |

| L100, L108, L110, L111, L118, L120, L130 102, 115, 125, 135, 145, 155C, 190C, LA100, LA110, LA120, LA130, LA140, LA150, LA105, LA115, LA125, LA135 LE, LA135 SE, LA145, LA155, LA165, LA175, D100, D105, D110, D120, D130, D140, D150, D155, D160, D170, E100, E110, E120, E130, E140, E150, E160, E170, E180 | Two 30-lb (14-kg) wheel weights, front Two 42-lb (19-kg) suitcase weights, rear |

| S240 | Two 34-lb (15-kg) wheel weights, front (4) 42-lb (19-kg) suitcase weights, rear |

| LT150, LT160, LT180, LT190, LTR180 | Two 34-lb (15-kg) wheel weights, front Two 31-lb (14.1-kg) plastic shell wheel weights, rear (not for LT190) |

| LX280, LX280AWS, LX289 X300, X300R, X304, X310, X320, X324, X340, X360 X330, X350, X350R, X354, X370, X380, X384, X390, X394 | Two 34-lb (15-kg) wheel weights, front Four 42-lb (19-kg) suitcase weights, rear |

| SST15, SST16, SST18 | One 88-lb (40-kg) weight kit, front Three 40-lb (18-kg) weights, rear |

| G100 | Two 50-lb (23-kg) wheel weights, rear Two 42-lb (19-kg) suitcase weights, rear |

| G110 | Two 50-lb (23-kg) plastic shell rear wheel weights |

| GT235, GT245 | Two 30-lb (14-kg) wheel weights, front Four 42-lb (19-kg) suitcase weights, front Four 42-lb (19-kg) suitcase weights, rear Four 50-lb (23-kg) wheel weights, rear Two 50-lb (23-kg) plastic shell wheel weights, rear |

| GX255, GX335, GX345, GX355 X500, X520, X530, X534, X540 X570, X580, X584, X590 | Two 30-lb (14-kg) wheel weights, front Four 42-lb (19-kg) suitcase weights, front Four 42-lb (19-kg) suitcase weights, rear Four 50-lb (23-kg) wheel weights, rear Two 50-lb (23-kg) wheel plastic shell weights, rear |

X465, X475, X485, X495, X575, X585, X595 | Four 42-lb (19-kg) suitcase weights, front Two 70-lb (32-kg) wheel cast-iron starter weights, rear Four 50-lb (23-kg) cast-iron wheel weights, rear Two 50-lb (23-kg) plastic shell wheel weights, rear Six 42-lb (19-kg) suitcase weights, rear |

Ordering information

Please contact a local John Deere dealer for availability and pricing information.

8Y Convertible Poly Utility Cart

Order number: LP22755

Oilite is a trademark of Beemer Precision, Incorporated.

10P Poly Utility Cart

10P Poly Utility CartEvery owner of a John Deere riding lawn and garden product is a potential customer for a high-quality, affordable utility cart.

Utility carts can be used to haul a variety of materials:

- Firewood

- Lawn debris

- Sand

- Dirt

- Mulch

- Garden tools

- Plants and bushes

The 10P Utility Cart is designed, painted, and decaled to be compatible with other John Deere equipment:

- Large 650-lb (295-kg) capacity

- 10-cu ft (283-L), heavy-duty, 0.25-in. (6.4-mm) thick poly bed

- Will not dent or rust

- 15x6 tubeless pneumatic tires with turf tread for maximum traction

- Easy, hands-free foot pedal dump release

- Steep dump angle for complete emptying

A convenient foot pedal dump release kit, LP48017, which now comes standard on all 10P and 17P carts is available to retrofit existing poly carts. This kit allows the operator to use both hands to lift the cart bed for more natural and efficient unloading.

Model comparison chart

Comparison with similar models

| Model | Order through | Box capacity (heaped) | Material thickness | Maximum weight | Vehicle compatibility |

| 7P | Order Zone | 7 cu ft (0.20 m3) | High-density polyethylene (HDPE)** | 450 lb* (204 kg) | EZtrak™, ZTrak™, 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 8Y | Order Zone | 8 cu ft (0.22 m3) | HDPE** | 300 lb* (136 kg) (tow) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 10P | Order Zone | 10 cu ft (0.28 m3) | Polypropylene | 650 lb* (295 kg) | EZtrak, ZTrak, 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 13 | Order Zone | 13 cu ft (0.37 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 16YS | Order Zone | 17 cu ft (0.48 m3) | Polypropylene | 800 lb (363 kg), 350 lb (158 kg) when using swivel feature to dump | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 17P | Order Zone | 17 cu ft (0.48 m3) | Polypropylene | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 18 | Order Zone | 18 cu ft (0.51 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | 100 Series, S240, X300 Series, X500 Series, X700 Series |

| 21 | Order Zone | 21 cu ft (0.59 m3) | 16-gauge, 0.06-in. (1.5-mm) steel | 1,000 lb* (454 kg) | X700 Series |

*The total weight of the cart and payload. For proper braking and operation, the loaded weight of the cart should never exceed the weight of the tractor, or other towing unit, plus the operator. The loaded weight of any equipment towed by an EZtrak or ZTrak mower should not exceed 250 lb (113.4 kg). The maximum weight for the 21 Utility Cart is rated at 20 mph (32.2 km/h).

**HDPE is compression molded for optimum thickness in all areas and maximum durability.

Specifications

7P | 8Y | 10P | 13 | 16YS | 17P | 18 | 21 | |

| Box capacity | ||||||||

| Heaped | 7 cu ft (0.20 m3) | 8 cu ft (0.22 m3) | 10 cu ft (0.28 m3) | 13 cu ft (0.37 m3) | 17 cu ft (0.48 m3) | 17 cu ft (0.48 m3) | 18 cu ft (0.51 m3) | 21 cu ft (0.59 m3) |

| Struck | 5.6 cu ft (0.16 m3) | 6.6 cu ft (0.19 m3) | 8.3 cu ft (0.24 m3) | 10 cu ft (0.28 m3) | 15 cu ft (0.42 m3) | 14 cu ft (0.40 m3) | 15 cu ft (0.42 m3) | 15 cu ft (0.42 m3) |