N500F SEPARATE FERTILIZER PLACEMENT AIR DRILL

Separate Fertilizer Placement (SFP) Air Drill

- Handle tough no-till conditions with ProSeries™ Opener

- See the flow rate of seed & fertilizer from the cab with RelativeFlow™ blockage monitoring

- Accurate seed placement & emergence with TruSet™ in-cab "closed loop" downforce pressure control

- Available in 30 ft., 40 ft., 43 ft., and 60 ft. sizes

View Product Brochure

Features

Down pressure adjustment for seed or fertilizer

Down pressure adjustment for seed or fertilizer Setting the opener down pressure is convenient and easy to adjust.

For 9.1-, 11.0-, 12.2-, and 13.1-m (30-, 36-, 40-, and 43-ft) widths the down pressure on the front fertilizer rockshaft is adjusted independently of the middle and rear seed opener rockshafts. Simply dial in the required pressure using the knobs.

The seed opener pressure gauge face is color coded to provide a guide for normal pressure operating ranges.

Valve block

Valve blockThe valve has two internal checks to reduce possibility of damage to valve when charging the system.

The down pressure cylinder is connected to live hydraulics and extends or retracts to maintain uniform down pressure on openers.

This system is compatible with either closed center or pressure flow compensated tractor hydraulic systems.

IMPORTANT: Tractors with open-center hydraulics require an open-center kit with change valve (order code 6505 to make the air drill compatible). The open-center application does not provide an opener flexibility feature.

Air Power 2 fan system

Air Power 2 fan systemEnhanced air seeding performance would not be possible without the updates to the 15,152.8-L (430-bu) and 19,381.5-L (550-bu) 1910 and C850 Air Carts. For the wider seeding width, more fan capacity has been added.

Air Power 2 provides two independently controlled fans – one for seed and one for fertilizer. Along with large, 76.2-mm (3-in.) primaries, more accurate delivery rates are possible across the full width of the seeding tool, from opener to opener. Plus, Air Power 2 allows growers to deliver high rates under field operating conditions – up to 40 percent more product delivery per primary compared to the single-fan system.

Dual fans are required for tow-between and tow-behind carts on the 23.2-m (76-ft) P576 and 18.3-m (60-ft) N560F models along with the eight primaries. Each fan will direct air to one set of primaries. Two selective control valves (SCVs) are required for the fans. The fan speed will be controlled through the SCV flow control.

Air Power 2 will also be compatible with the 17.1-m (56-ft) P556 and 23.2-m (76-ft) P576 Air Hoe Drills, as well as the 13.1-m (43-ft) N543F and 18.3-m (60-ft) N560F Disk Drills, plus the 15.2-m (50-ft) and 18.3-m (60-ft) 1890 models. An option is available for stainless-steel primaries to resist corrosion from high fertilizer rates.

C850 Air Cart

C850 Air CartThere is a slide at the meter to choose bottom or top shoot for each meter. There is also a valve on the tank pressure system to choose top or bottom shoot. This same valve is used to adjust the amount of air to the tank to create the proper pressure differential.

Tank pressure valve

Tank pressure valveThe arrow on the valve handle should be pointing to the top of the range for the top shoot and the bottom of the range for the bottom shoot. If the tank will not be in use, set the pressure valve to the middle setting to not pressurize the tank. The operator should use the gauge to find the correct setting. An electronic pressure sensor will send a warning to the display if the tank pressure differential is out of range.

If pressure is in the green operating range, the tanks are sealed and operating correctly. The electronic pressure sensor is located behind the mechanical gauge on the side of the cart.

RelativeFlow blockage sensing

RelativeFlow blockage sensingWith the RelativeFlow blockage system, operators can see the flow rate of both seed and fertilizer from inside the tractor cab. Sensors on delivery hoses monitor the relative rate of product flow. An easy-to-read display clearly visualizes relative product flow across the drill, from opener to opener. This exclusive technology gives a better view of what is happening across the tool in order to spot problems before blockage occurs.

RelativeFlow Blockage is available on the following models:

- P540 - 12.2-m (40-ft)

- P556 - 17.1-m (56-ft)

- P576 - 23.2-m (76-ft)

- N500C - all widths

- 1890 - 15.2-m (50-ft) and 18.3-m (60-ft)

- N530F - 9.1-m (30-ft)

- N540F - 12.2-m (40-ft)

- N543F - 13.1-m (43-ft)

- N560F - 18.3-m (60-ft)

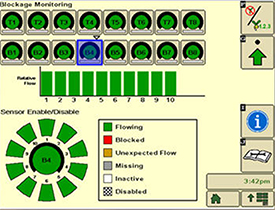

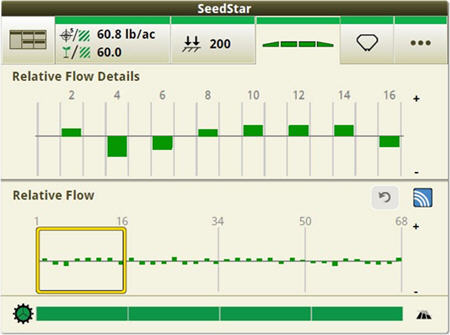

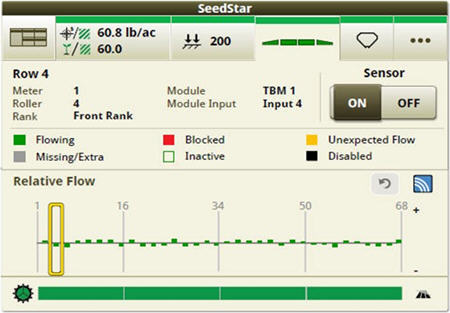

Below are the GreenStar™ 3 2630 Display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

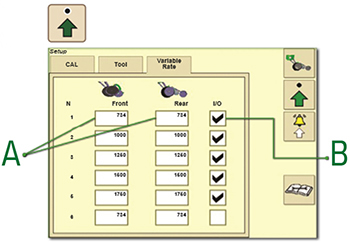

Blockage monitoring screen

Blockage monitoring screenThe RelativeFlow system chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

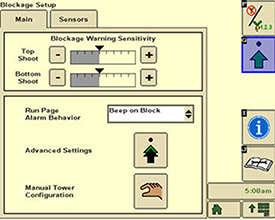

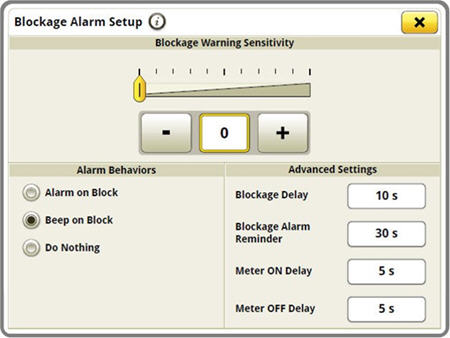

Blockage set-up screen

Blockage set-up screenBlockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage set-up screen

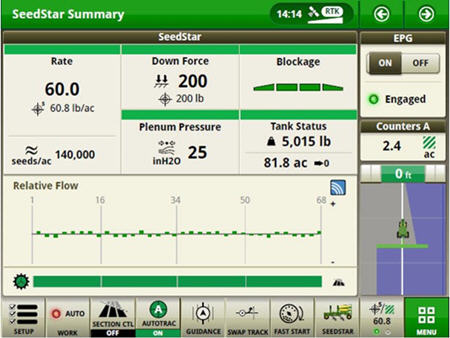

Blockage set-up screenBelow are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run pageThe SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Operators can zoom into flow details by meter section when selecting Blockage tiles

Operators can zoom into flow details by meter section when selecting Blockage tiles Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

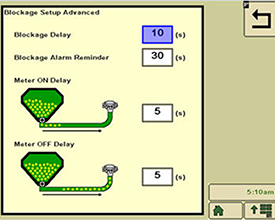

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screenBlockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

- A blockage delay is how long a blockage should occur before an alarm is sounded.

- The blockage alarm reminder is how often the alarm should sound when a blockage occurs.

- The meter on delay is the time from when the meter is turned on until the blockage sensor should start monitoring for blockage.

- The meter off delay is the time from when the meter is turned off until the blockage sensor should start monitoring to verify no flow.

For more detailed information, see the owner’s manual.

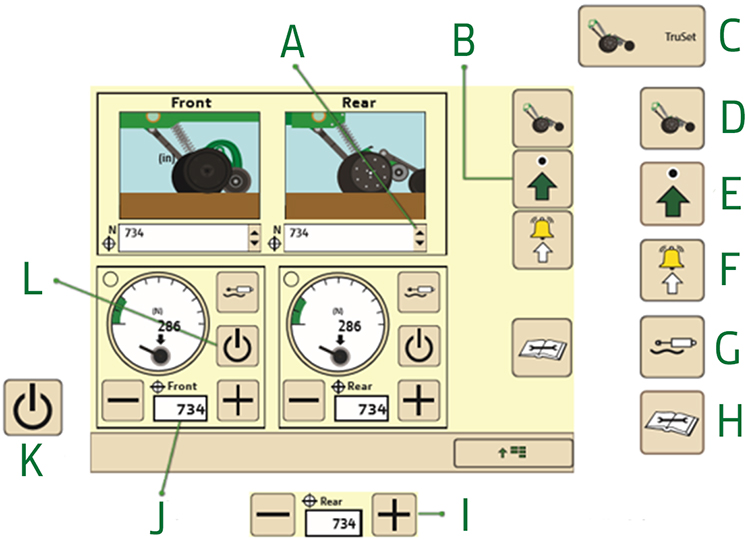

Downforce control from the cab

Downforce control from the cabTruSet downforce control enables operators to conveniently set values for the seed and fertilizer ranks independently from the cab. This feature enables them to meet optimal downforce pressure while in varying soil conditions. TruSet downforce control improves seed placement accuracy in varying field conditions, leading to improved emergence and plant maturity.

TruSet system quick-reference guide

TruSet system quick-reference guide image key:

- Select here to choose from a list of programmed downforce setpoints.

- Select here to enter calibration screens, input downforce setpoints, and to verify the tractor selective control valve (SCV) controlled by automation.

- TruSet – main menu button

- TruSet run screen

- Setup – select to configure tool

- Warning Setup – select to set downforce warnings

- Float Mode – select to toggle the float mode on and off. This option is only available using Power Beyond control options.

- Diagnostics – select to enter diagnostic information

- Press the plus or minus button to increase or decrease the downforce.

- Enter a value here to increase or decrease the downforce.

- Enables the downforce system

- Disables the downforce system

TruSet system tool setup

Tool setup

Tool setupSelect the tool setup to enter calibration screens, input downforce setpoints, and to verify the tractor SCV controlled by automation:

- Enter target setpoint for downforce

- Enable pick 6 prescription

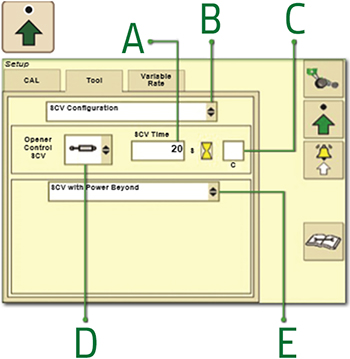

TruSet system tool setup - automated SCV

TruSet system tool setup - automated SCV image key:

- This is the time that the SCV remains on to ensure that Power Beyond activates.

- Select SCV configuration

- Enable or disable continuous SCV time

- Select opener control SCV (SCV1-6)

- Select opener control (SCV with Power Beyond, SCV only)

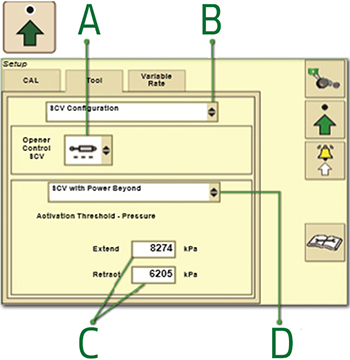

TruSet system tool setup - manual SCV

TruSet system tool setup - manual SCV image key:

- Select opener control SCV Manual (---)

- Select SCV configuration

- Enter values for the extend and retract thresholds if necessary

- Select opener control (SCV with Power Beyond, SCV only)

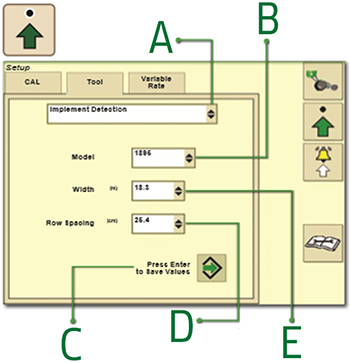

TruSet system tool setup - Implement Detection

TruSet system tool setup - Implement Detection image key:

- Select Implement Detection

- Select tool mode

- Press to save the values

- Select row spacing

- Select nominal tool width

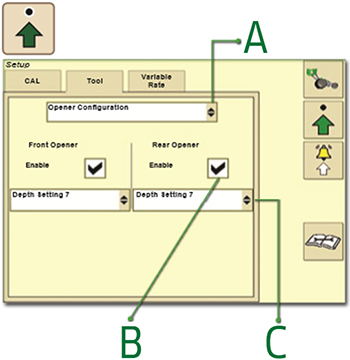

TruSet system tool setup - opener configuration

TruSet system tool setup - opener configuration image key:

- Select opener configuration

- Enable and disable opener control

- Select opener depth setting (1 through 13)

SPF Openers

SPF OpenersSeparate fertilizer placement offers nutrient placement at a 5 or 7-degree angle

The 5-degree fertilizer opener:

- Is required for liquid and anhydrous (NH3) fertilizers

- Will also apply dry fertilizer

- Opens a smaller trench than the 7-degree opener

- Is better able to capture anhydrous and liquid fertilizer and seal fertilizers in the soil

Fertilizer tubes

There are four choices of interchangeable fertilizer tubes:

- Dry fertilizer tube to be used with 32-mm (1-1/4-in.) secondary fertilizer hose from the 1910 Cart

- Liquid fertilizer tube (for 13-mm [1/2-in.] i.d. hose)

- IMPORTANT: Using this tube for anhydrous may cause loss of retention

- Dual fertilizer delivery tube – allows for placement of dry or anhydrous. If applying both simultaneously, the operator may need to provide a relief system to relieve air from dry tube for adequate anhydrous retention. Without air relief, the operator will need to adjust air plenum to restrict all airflow to SFP dry tubes when anhydrous is being applied

- Anhydrous tube (for 10-mm [3/8-in.] i.d. hose)

- Liquid or NH3 fertilizer metering/delivery system is not provided by the John Deere Seeding Group

Key features of the SFP opener are:

- 457.2-mm (18-in.) opener blades operate at 5 degrees, resulting in a narrow trench with less soil disturbance

- Fertilizer tubes are interchangeable among dry, liquid, or anhydrous (NH3)

- Closing wheel assembly is closer to the fertilizer delivery tube; provides increased fertilizer retention

- Serrated closing wheels are base equipment on anhydrous openers and optional on liquid and dry openers

- NOTE: Closing wheels are recommended when dry soil conditions are common.

- Extended-wear (chrome alloy) fertilizer boots are standard equipment

- Choice of five different gauge wheels

- Depth adjustments in 6-mm (1/4-in.) increments from 13 mm to 89 mm (1/2 in. to 3.5 in.) deep

Opener furrow-closing wheel

The 25-mm x 305-mm (1-in. x 12-in.) cast closing wheel follows the press wheel to close the furrow, placing soil over seed or fertilizer after the press wheel secures the seed in the furrow.

- A double-row ball bearing to reduce wear is located in the arm of the closing wheel

- Mounted parallel to the furrow opener, the closing wheel can be adjusted laterally to allow running on top of the furrow for sandy or mellow soils or to side of the furrow for heavier soils

- Down pressure is adjustable from 11.8 kg to 19.5 kg (26 lb to 43 lb) (no tools and three adjustments)

- A grease fitting in the pivot arm provides free movement for the arm

ProSeries Openers

ProSeries OpenersProSeries Openers are in base equipment on all 1890 and N500F Separate Fertilizer Placement (SFP), 1990 Central Commodity System (CCS™), and 1590 Air Drills.

On the 1890 models, the single-disk openers are on 190-mm (7.5-in.) or 254-mm (10-in.) row spacing. On 15.25-m (50-ft) and 18.3-m (60-ft) 1890 models, the 190-mm/380-mm (7.5-in./15-in.) or 254-mm/508-mm (10-in./20-in.) dual-row spacing feature is in base equipment. The single-disk openers provide consistent and accurate seed placement.

The ProSeries Openers are gang mounted and are hydraulically raised and lowered. The hydraulic downforce system also offers a wide range of downforce settings for the openers.

Active hydraulic downforce pressure valve

Active hydraulic downforce pressure valveThe active hydraulics:

- Work in conjunction with the opener spring

- Provide an adjustable range of 75 kg (165 lb) to 180 kg (400 lb) of down pressure per opener

- Benefit: penetrate hard soils and heavy residue

- The cylinders allow the openers to travel up or down an additional 405 mm (16 in.) with active hydraulic down pressure to follow the ground

- Provide the openers additional pressure when needed or allow the openers to go into relief if the pressure becomes too high

The down pressure:

- Is easily adjusted with the pressure valve located on the front of the mainframe

- Provides the operator the ability to quickly adjust, or dial in, the down pressure as operating conditions change

NOTE: For additional ballast in hard-to-penetrate conditions, tractor suitcase weights may also be added to the mainframe and wings to obtain maximum down pressure per opener.

The ProSeries Openers:

- Work not only in no-till conditions, but also in minimum or reduced-till conditions

- Provide 51 mm (2 in.) of free travel in the opener before spring down pressure takes over

- Benefit: allows the opener to move over uneven ground conditions and minimize the chance of the gauge wheels bulldozing soil in soft or mellow conditions

- The opener spring travels a maximum of 203-mm (8-in.) up or 150-mm (6-in.) down before the hydraulics react to uneven seedbeds

Tractor, cart, and display compatibility

The 18.3-m (60-ft) tool is five sections with 254-mm (10-in.) spacing and is Air Power™ 2 compatible. This larger tool will require a 15,152.8-L (430-bu) tow-between cart, a 15,152.8-L or 19,381.5-L (430-bu or 550 bu) tow-behind cart, or the C850 Air Cart with Air Power 2 dual fan system. Along with this cart compatibility, breaks are required for this configuration due to the weight of the drill and cart versus the tractor during transport mode. Below are compatible tractor, horsepower, display, and engine specific details.

Cart compatibility

- 1910 Carts equipped with Air Power 2

- 15,152.8-L (430 bu) tow-between cart

- 15,152.8-L (430 bu) tow-behind cart

- 19,381.5-L (550 bu) tow-behind cart

- C850 Air Cart

Along with the added tool size, the N500F offers a heavy-duty hitch to pull an additional 20,412 kg (45,000 lb), which is the equivalent of two 7570-L (2,000-gal.) NH3 tanks when using a tow-between cart.

Tractor compatibility

Cart and tractor compatibility

Cart and tractor compatibility- Recommended minimum 425-kW (570-hp) tractor with a 295.3-L/min (78-gpm) high-flow pump

- Follow recommended ballasting guidelines

- Requires a tractor with four selective control valves (SCVs) plus power beyond

- Requires a brake port for 1910 and C850 Air Cart brakes

- Flat ground - seeding less than 2.5 cm (1 in.)

- 425 kW (570 hp)

- Flat ground - seeding greater than 2.5 cm (1 in.)

- 462.3 kW (620 hp)

- Hilly terrain - seeding at any depth

- 462.3 kW (620 hp with tracks - recommended to obtain proper wheel slip)

- Flat ground - seeding less than 2.5 cm (1 in.)

Engine power capabilities

Engine power to pull carts

Engine power to pull carts- The seeding tool system must be compatible with the maximum power that the largest Final Tier 4 (FT4) or comparable manufacturer’s tractor can produce.

- FT4 tractors have an advertised engine horsepower of up to rated power level of 462.3 kW (620 hp). Power bulge for short periods of time increase this to 499.6 kW (670 hp).

- Pulling a full 15,152.8-L (430-bu) cart requires about 51.5 kW (69 hp), the 19,381.5-L (550-bu) cart requires about 66.4 kW (89 hp), and the 29,953.2-L (850-bu) cart requires about 96.9 kW (130 hp).

Display compatibility

Display compatibility with carts

Display compatibility with cartsThis larger tool was designed for the Gen 4 CommandCenter™ display. This technology integration saves time and money.

- 4600 CommandCenter™ display with Premium Activation

- 4640 Universal Display with core activation

Growers that may be interested in upgrading their current 90 Series Openers to the ProSeries Openers can do this by ordering a ProSeries performance upgrade kit.

Two kit offerings are available for seed openers, a two row (AA98693) and eight row (AA97392) kit. The breakdowns are as follows:

AA98693

| A105410 | Deflector, seed firmer tab | 2 pc |

| A107506 | Washer, special | 8 pc |

| A109343 | Seed boot, left hand | 1 pc |

| A109344 | Seed boot, right hand | 1 pc |

| A110307 | Closing arm spring, left hand | 1 pc |

| A110308 | Closing arm spring, right hand | 1 pc |

| A31869 | Locknut | 2 pc |

| AA88056 | Press wheel assembly | 2 pc |

| E55662 | Nut, 3/8 | 8 pc |

| N280653 | Washer | 2 pc |

| N283804 | Opener disk | 2 pc |

| N283976 | Nut, U-nut | 2 pc |

| N283308 | Screw, flange | 2 pc |

| 03H2070 | Bolt, round head | 8 pc |

| 19M7720 | Screw, hex | 2 pc |

| A105392 | Spiked seed closing wheel | 2 pc |

| A97699 | Instructions, dealer download | 1 pc |

AA97392

| A105410 | Deflector, seed firmer tab | 8 pc |

| A107506 | Washer, special | 32 pc |

| A109343 | Seed boot, left hand | 4 pc |

| A109344 | Seed boot, right hand | 4 pc |

| A110307 | Closing arm spring, left hand | 4 pc |

| A110308 | Closing arm spring, right hand | 4 pc |

| A31869 | Locknut | 8 pc |

| AA88056 | Press wheel assembly | 8 pc |

| E55662 | Nut, 3/8 | 32 pc |

| N280653 | Washer | 8 pc |

| N283804 | Opener disk | 8 pc |

| N283976 | Nut, U-nut | 8 pc |

| N283308 | Screw, flange | 8 pc |

| 03H2070 | Bolt, round head | 32 pc |

| 19M7720 | Screw, hex | 8 pc |

| A105392 | Spiked seed closing wheel | 8 pc |

| A117632 | Instructions, ProSeries | 1 pc |

ProSeries seed opener kit

ProSeries seed opener kitNOTE: Kits are subject to change.